Everything you need to know about warehouse management systems (WMS) and how to choose the right one for your business.

Everything you need to know about warehouse management systems (WMS) and how to choose the right one for your business.

A Warehouse Management System (WMS) is a software solution (ideally cloud-based) that gives merchants visibility into their fulfillment operations. A WMS tracks inventory from the moment it arrives at the warehouse to the moment it leaves on a last mile delivery vehicle. On the warehouse end, it’s used for everything from high-end management functions to processing inbounds and picking and packing.

Warehouses use a WMS to ensure that the movement of goods through the warehouse is as efficient as possible to avoid inventory shrinkage and dedicate labor hours to the functions that matter most for on-time fulfillment: picking, packing, and shipping.

Warehouse management is the process by which merchants and warehouses work together to improve efficiency and decrease operating costs of storage and fulfillment. Warehouse management encompasses both digital processes like inventory reporting and manual ones like slotting SOP’s that drive greater efficiency.

WMS should automate as many warehousing and fulfillment processes as possible via direct shopping cart integrations, marketplace integrations (ie Walmart Marketplace and Amazon), and electronic data interchange (EDI) connectors. As selling becomes increasingly complicated due to multichannel fulfillment, the WMS provides visibility into day-to-day operations and logistics and delivery statuses.

A WMS that seamlessly integrates with a merchant’s ecommerce shopping cart and marketplace listings eliminates the need for multiple spreadsheets and manual order uploads. It also cuts down on customer service requests by sending customers regular updates on their fulfillment status and real-time delivery tracking.

This level of integration allows sellers to forecast future demand and anticipate supply chain activities to take the guesswork out of inventory re-ordering and inventory distribution. Eventually, quickly-growing merchants may even be able to sell products without ever having physical possession of merchandise.

Ultimately, eCommerce merchants that rely on a powerful WMS as part of their digital warehousing strategy make more efficient use of their time and money, allowing them to focus more resources on product development, marketing, and customer service.

A powerful WMS not only streamlines operations within the warehouse, but also feeds efficiency upstream within the overall supply chain. The right WMS will offer inventory insights and demand forecasting tools that help merchants determine:

Optimizing eCommerce Operations with a Warehouse Management System

eCommerce sales channels have evolved rapidly to help merchants scale their sales operations. Because ecommerce sales are all managed digitally, they handle growth seamlessly and inexpensively. However, many merchants face the challenge of scaling their fulfillment operations at the same pace to meet growing demand from their sales channels. This is where a powerful WMS can stand in the gap and help to digitize warehousing and fulfillment.

Children’s furniture and toy retailer, ECR4Kids, found that when they relied on technology for their ecommerce fulfillment, they had the confidence to scale up quickly with spikes in demand.

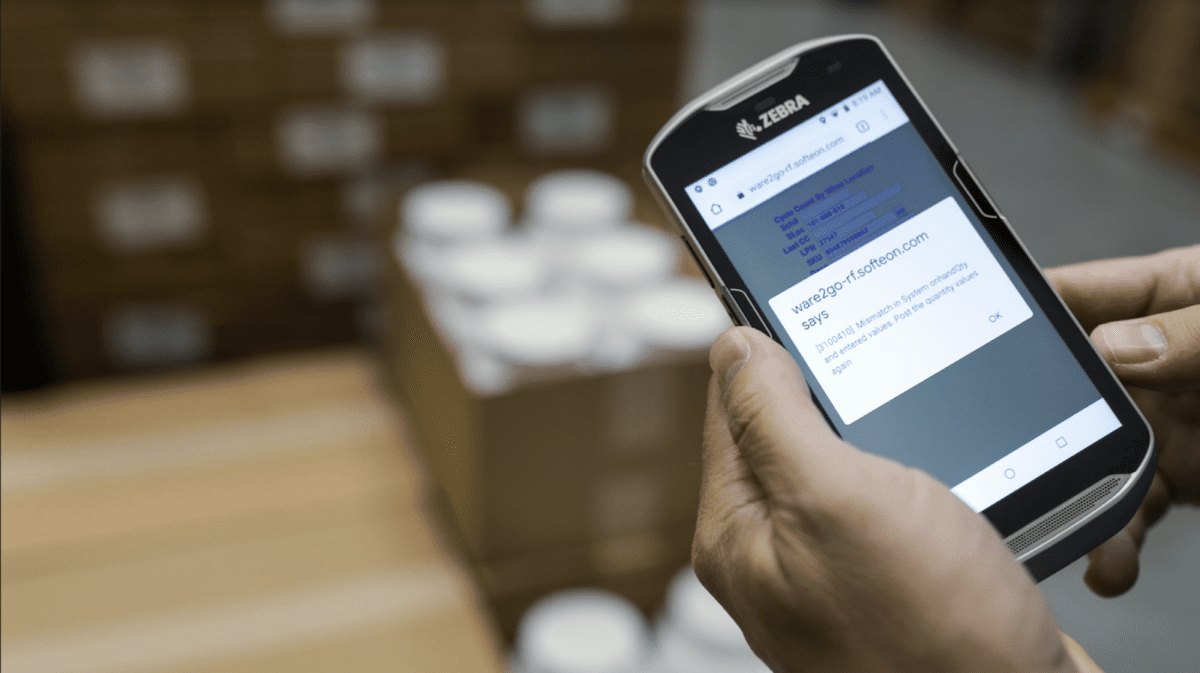

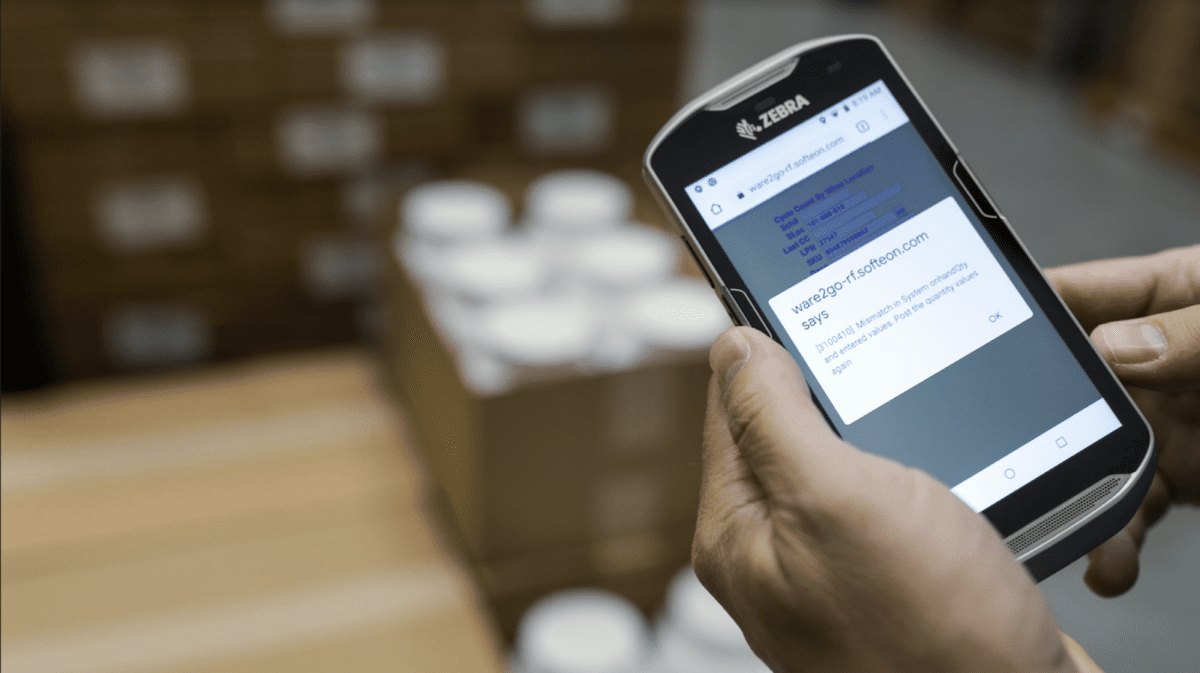

Integrating all sales channels through a single WMS platform also makes inventory, sales, and shipping data much more actionable. For instance, the WMS lets merchants determine real-time stock availability, forecast inventory accuracy, and set reorder points in advance to mitigate shortages. It also enables highly accurate inventory cycle counts to reduce inventory shrinkage or obsolescence.

What’s more, this data can also be used to improve delivery speed and control bottom line costs. A smart WMS will utilize machine learning to recognize patterns in sales and shipping data to help ecommerce merchants understand where their best customers are located and their average price per shipment. With this data, merchants can choose warehouse placement that gets their inventory closer to their end customers, enabling 1 to 2-day ground shipping no matter where their customers are located. The benefits of a smarter distributed warehouse network are 2-fold:

Any merchant who has partnered with a small or regional 3PL knows that not all WMS are created equal. Often, regional 3PL’s will employ a Standalone WMS. These systems are typically housed on the warehouse’s server and only track functions within the warehouse. They support receiving and put-away tracking as well as pick, pack, and ship and inventory cycle counts. They often rely on manual processes but serve their purpose for small businesses operating from a single warehouse.

When businesses are ready to expand their warehouse distribution footprint to offer nationwide 1 to 2-day ground shipping, they may first opt to add more regional 3PL’s to their network. However, if each of these regional 3PL’s is operating on its own Standalone WMS, merchants will be stuck in the middle, switching between WMS platforms to monitor inventory levels and fulfillment statuses at each 3PL.

Businesses looking to gain more visibility into their fulfillment in order to scale quickly would be better served by an Integrated ERP System or an Cloud-based Warehouse Management System. An Integrated ERP will enable merchants to integrate their accounting, supply chain planning, and CRM functions into their WMS. While a Cloud-based WMS that connects all fulfillment centers across their network to give a high-level view of inventory levels and order and fulfillment statuses.

Ware2Go’s WMS, FulfillmentVu features an open API that integrates with over 70 ecommerce and retail technologies. It serves as a single connection point between fully sales channels and full-service fulfillment capabilities. Ware2Go’s distributed network is flexible and adaptable to scale quickly with shifts in demand or channel requirements. FulfillmentVu’s key features include:

FulfillmentVu’s advanced fulfillment capabilities connect Ware2Go’s nationwide 1- to 2-day delivery network. It is supported by Ware2Go’s rigorous service level agreement (SLA), which guarantees 99% accurate and on-time fulfillment, a 48-hour dock to stock time, and same-day fulfillment for all orders received before 3:00 PM. Merchants are also supported by Ware2Go’s dedicated client support team and data analysts who help identify opportunities for cost savings and revenue growth with regular reporting and analysis.

To learn more about Ware2Go’s best-in-class WMS, reach out to one of our fulfillment experts.